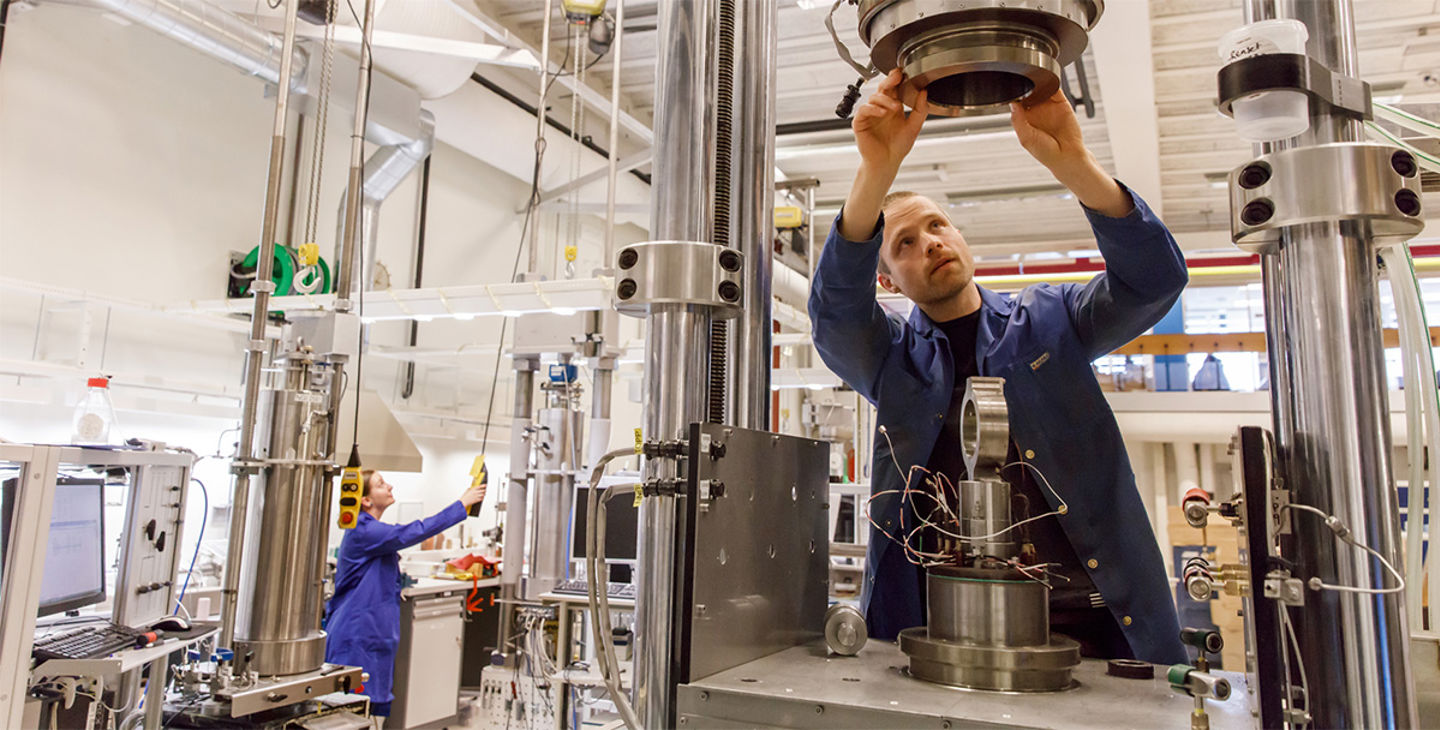

Rock mechanics laboratory

NGI has an advanced rock mechanics laboratory with equipment for geomechanical and geophysical testing of rock samples at high stress and temperature.

High-quality rock mechanics and geophysical datasets are essential for various applications within the petroleum industry, geothermal energy production, and storing CO2 and radioactive waste. Examples are:

- well stability

- sand production

- hydraulic fracturing

- reservoir flow

- compaction and surface subsidence

- the integrity of faults and roof rock

- rock physics and geophysical studies

- instrumentation and monitoring

NGI offers

- test facilities for standardized and specialized tests (e.g., R&D purposes)

- workshop for the design and production of own laboratory equipment, including instrumentation

- expertise and software for the design and analysis of laboratory experiments

The following tests are offered:

- classification and index testing

- simple strength tests

- uniaxial compressive strength/ compressive strength ("UCS test")

- indirect tensile strength/ tensile strength ("Brazil test")

- point load test - triaxial testing (standard)

- shear test with isotropic or anisotropic consolidation (drained/undrained)

- compaction test (1D/K0) and oedometer testing

- the possibility of a flexible stress path and cycling of total stress and pore pressure

- measurement of thermal expansion coefficient

- permeability testing

- HPHT- High-pressure and high-temperature testing - geophysical/rock physics tests

- measurements of ultrasonic P and S wave velocities and electrical resistivity can be made in all triaxial cells - acoustic emission (AE) testing

- AE testing in our own specially adapted triaxial setup - CO2 flow tests

- multiphase flow at different temperature and pressure conditions (including supercritical CO2) in combination with geophysical measurements - triaxial test in CT scanner

- visualization of deformation and fluid flow, including geophysical measurements - direct shear test (shear box test)

- friction and deformation characteristics of cracks

- fluid flow and conductivity on the fracture plane

- "Velocity stepping test," varying shear speed for assessing the seismic potential of cracks and faults - advanced characterization

- CT scanner for 2D and 3D visualization (structures, fracture pattern, etc.)

- microscope (optical and SEM) for microtexture

- photogrammetry for characterizing the crack surface

Magnus Soldal

Head of Rock mechanical and geophysical testing Rock Mechanical and Geophysical Testing Magnus.Soldal@ngi.no+47 411 29 454